I needed a way of retaining the dome, but allowing easy removal. For both BHD and X2 i managed to get the dome electronics to connect with the removal of the dome. I hated fishing for wires and connecting after docking. So Juice needed similar.

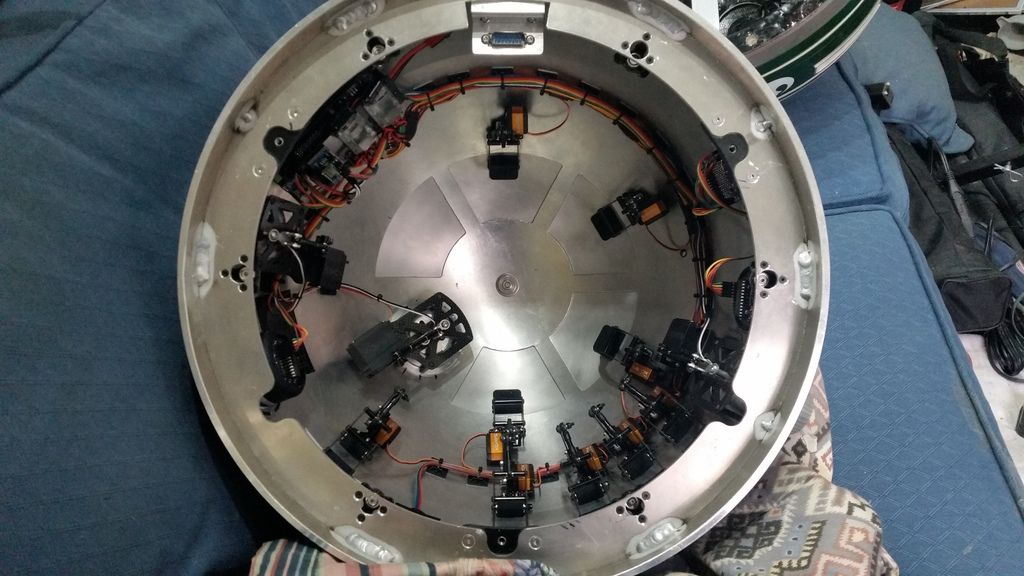

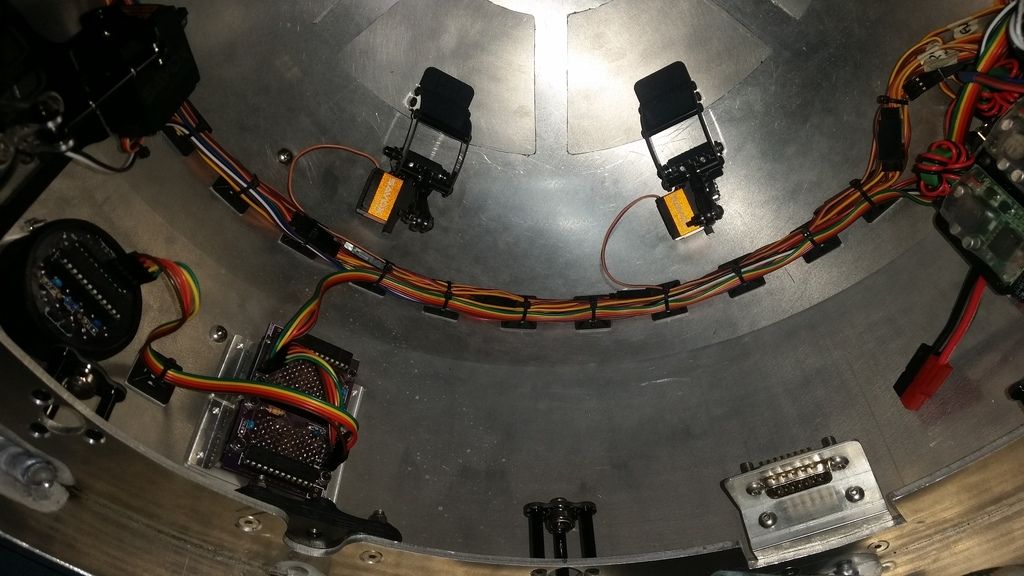

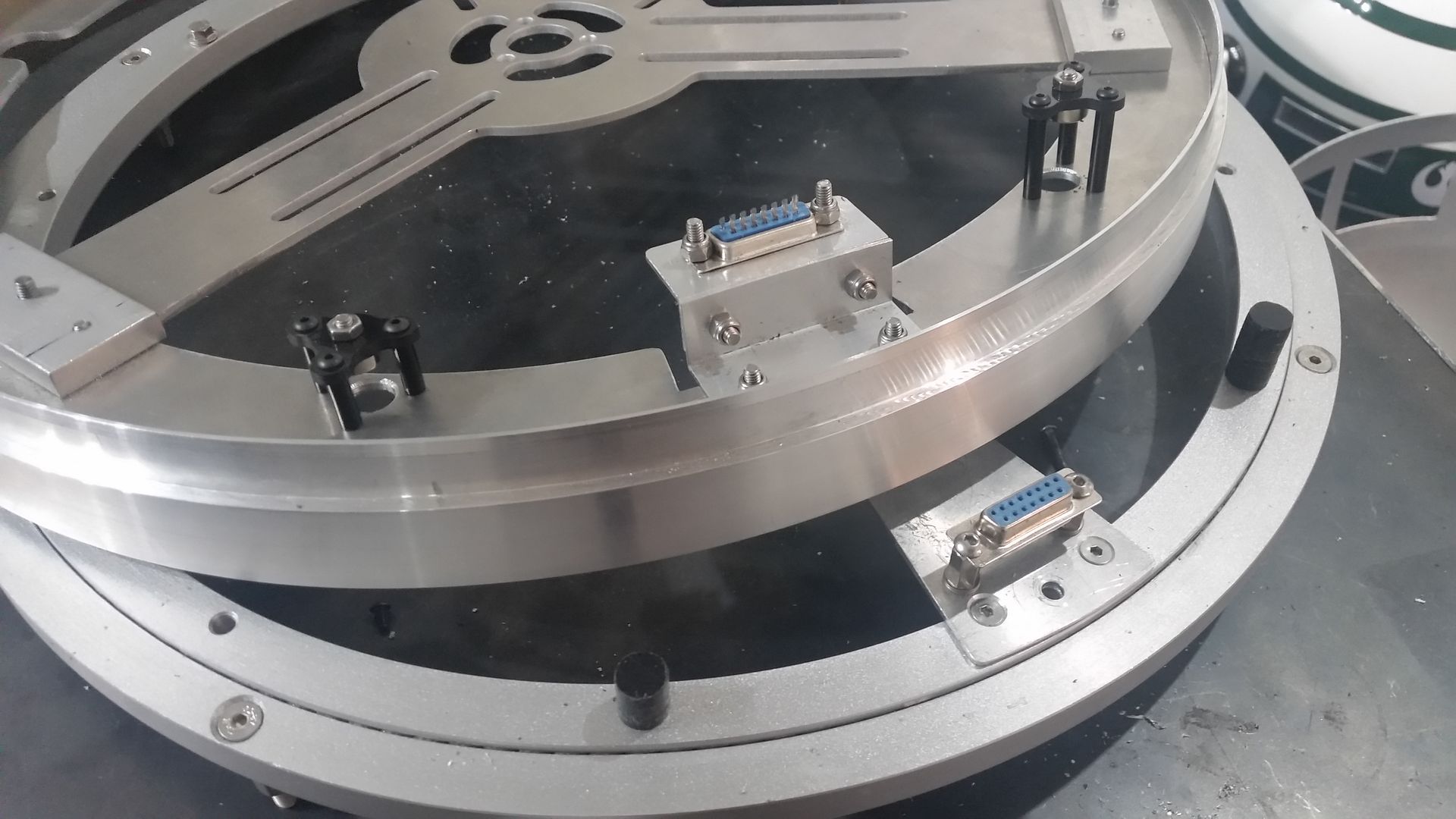

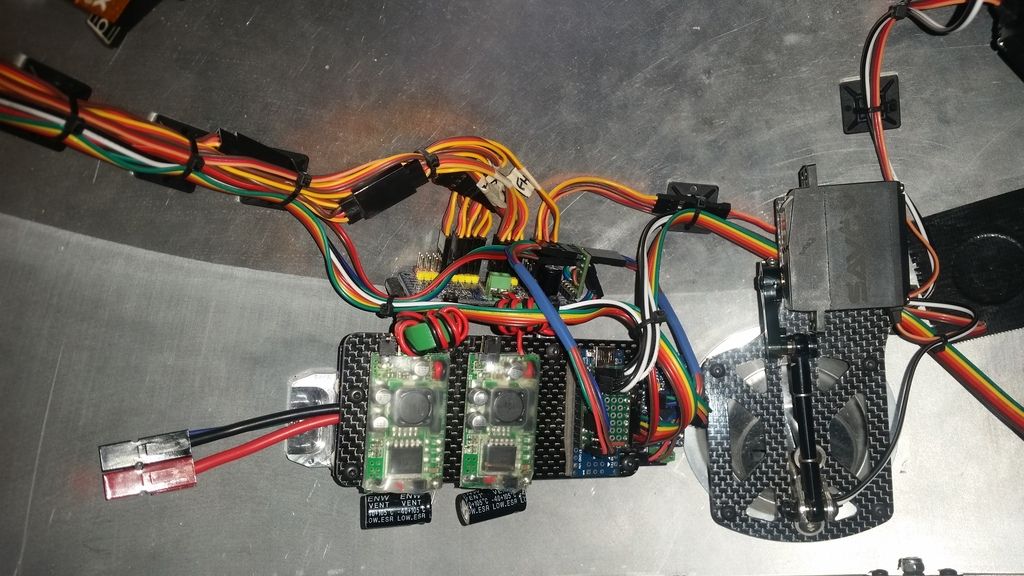

I am using a 12 channel slip ring this time. Just for 12v (5 lines), Gnd (5 lines) and I2C pair. So 15pin connectors would be fine. In addition X2 used magnets to retain the dome and steel studs to align it. And i hoped to do the same for Juice.

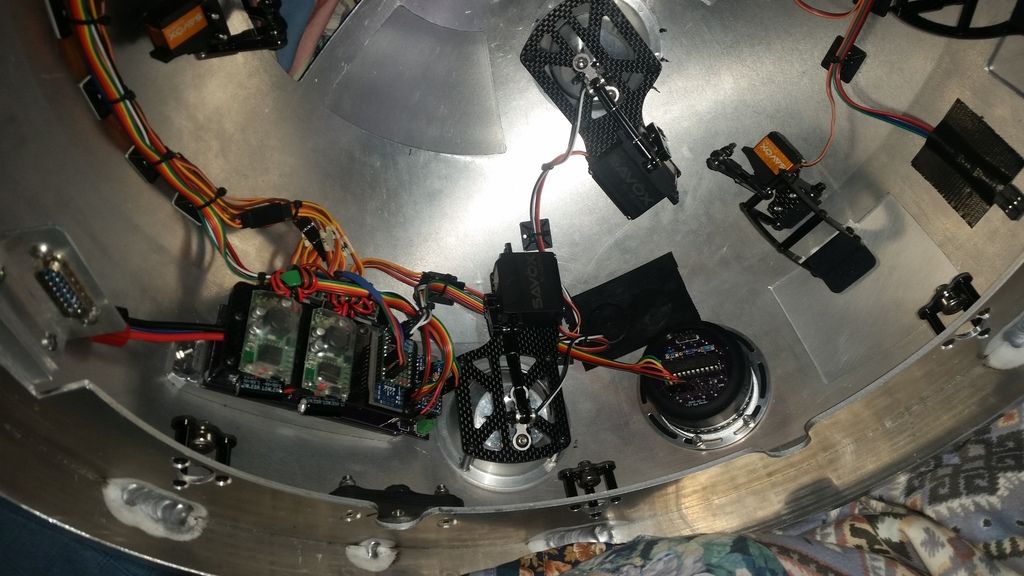

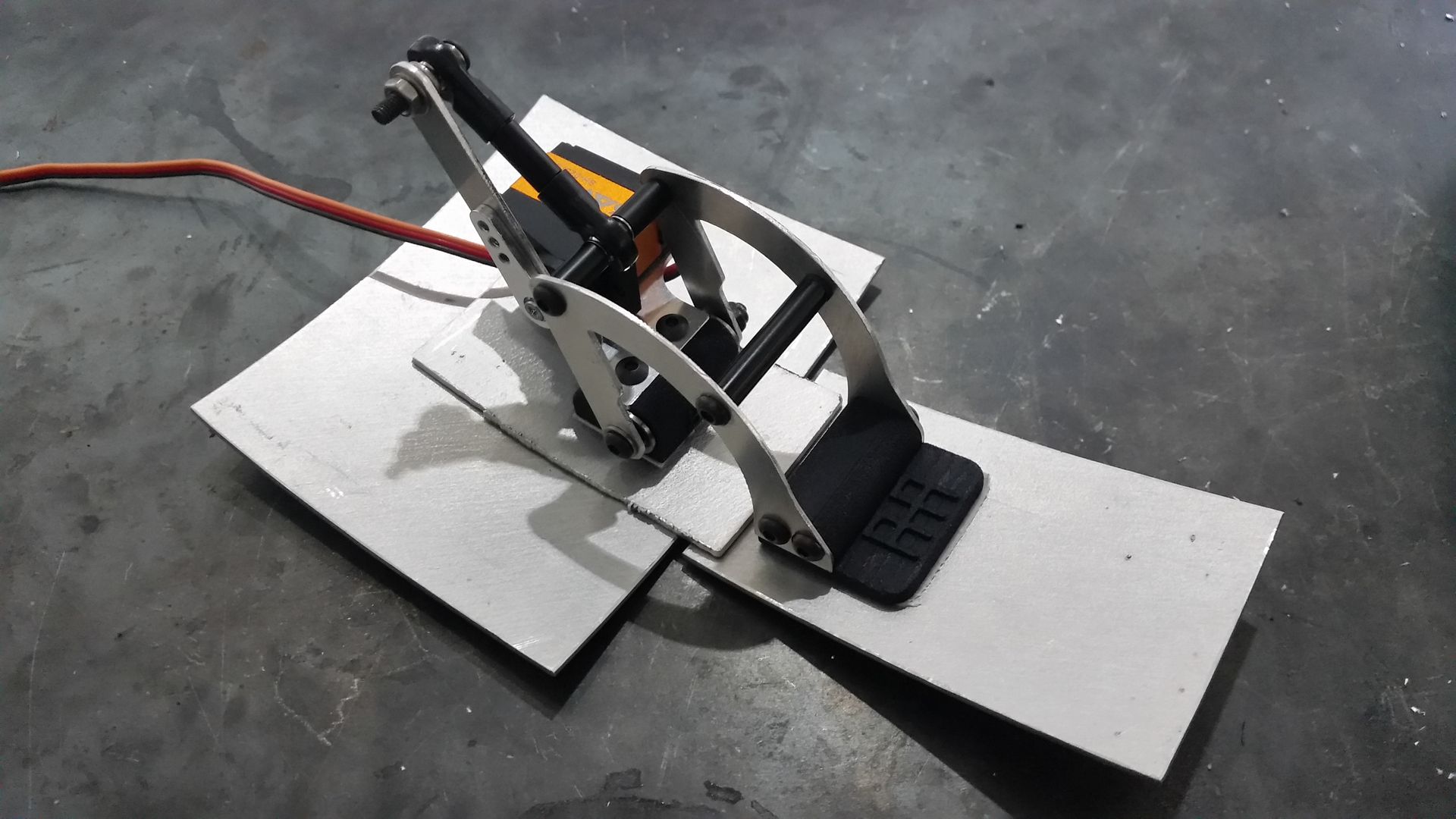

So i removed a section of the dome base ring, to allow the connector to be close to the rockler, and mounted a bracket to hold the dome end connector. Then an arm to the inner rockler to house the droid end connector and support the wire and any additional connectors from the slip ring.

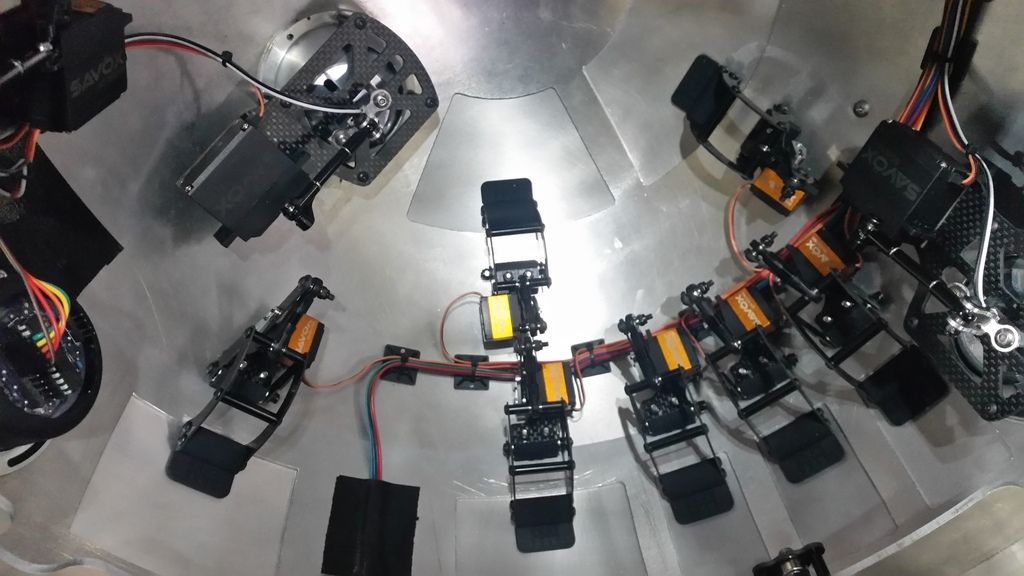

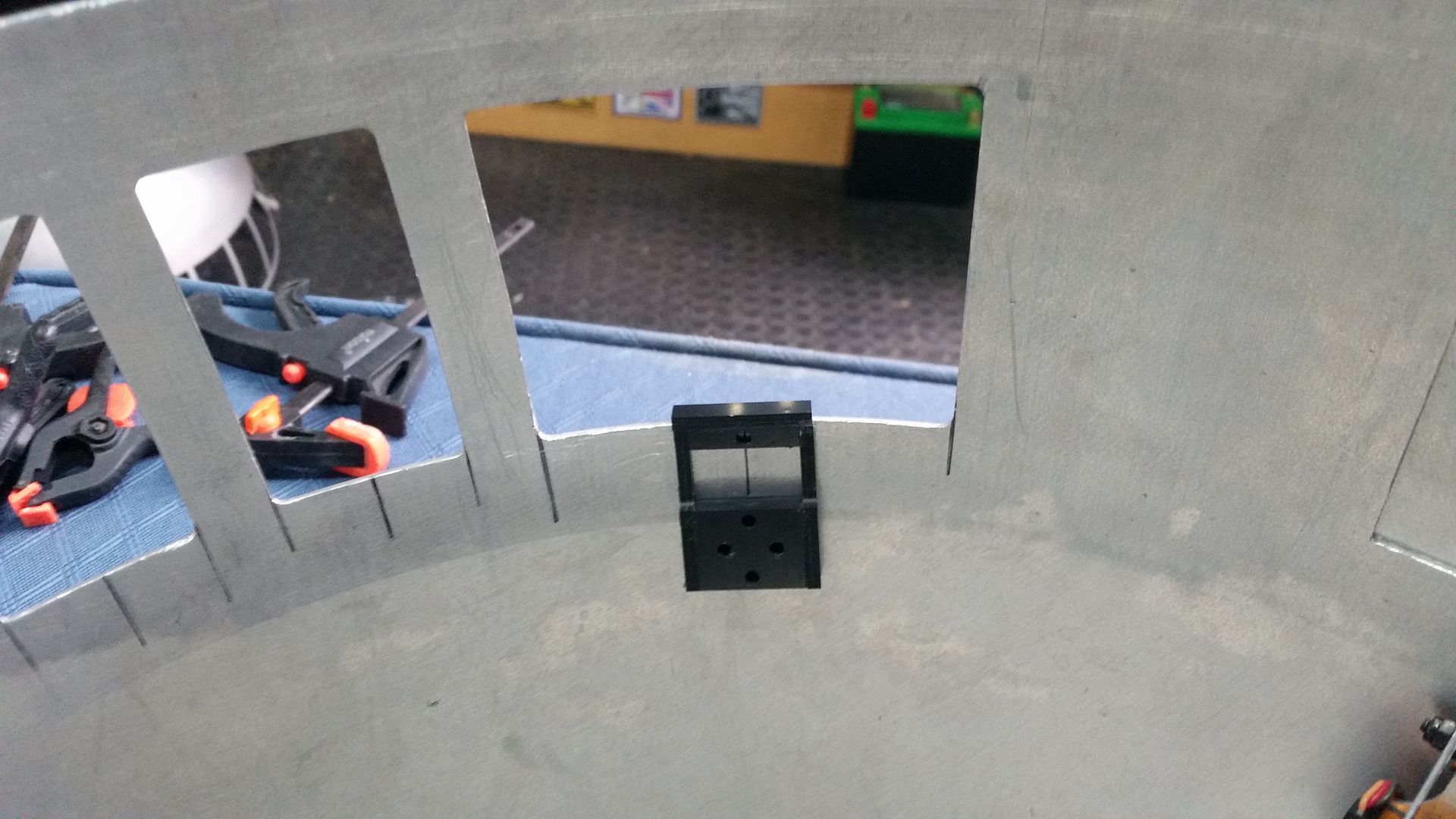

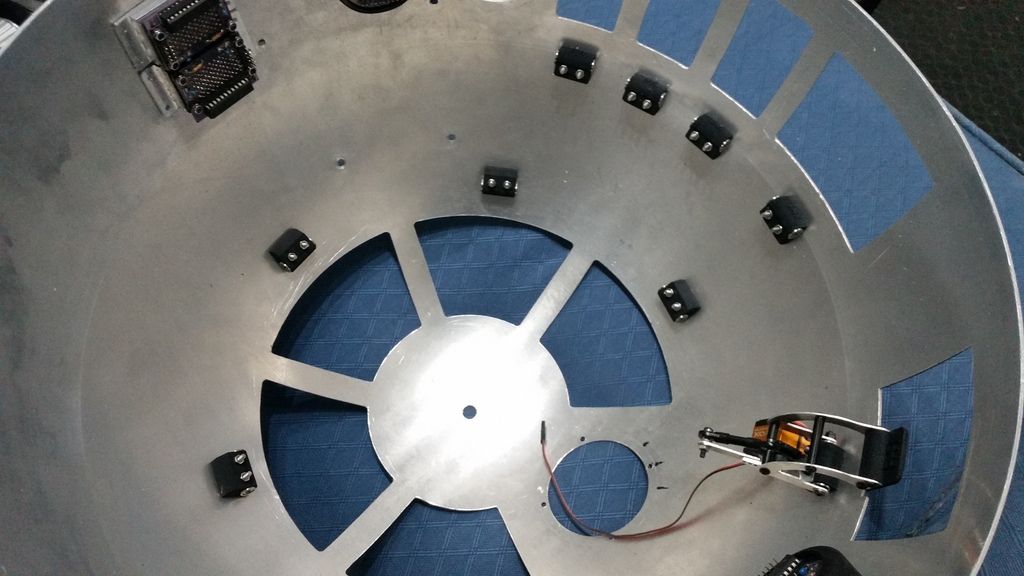

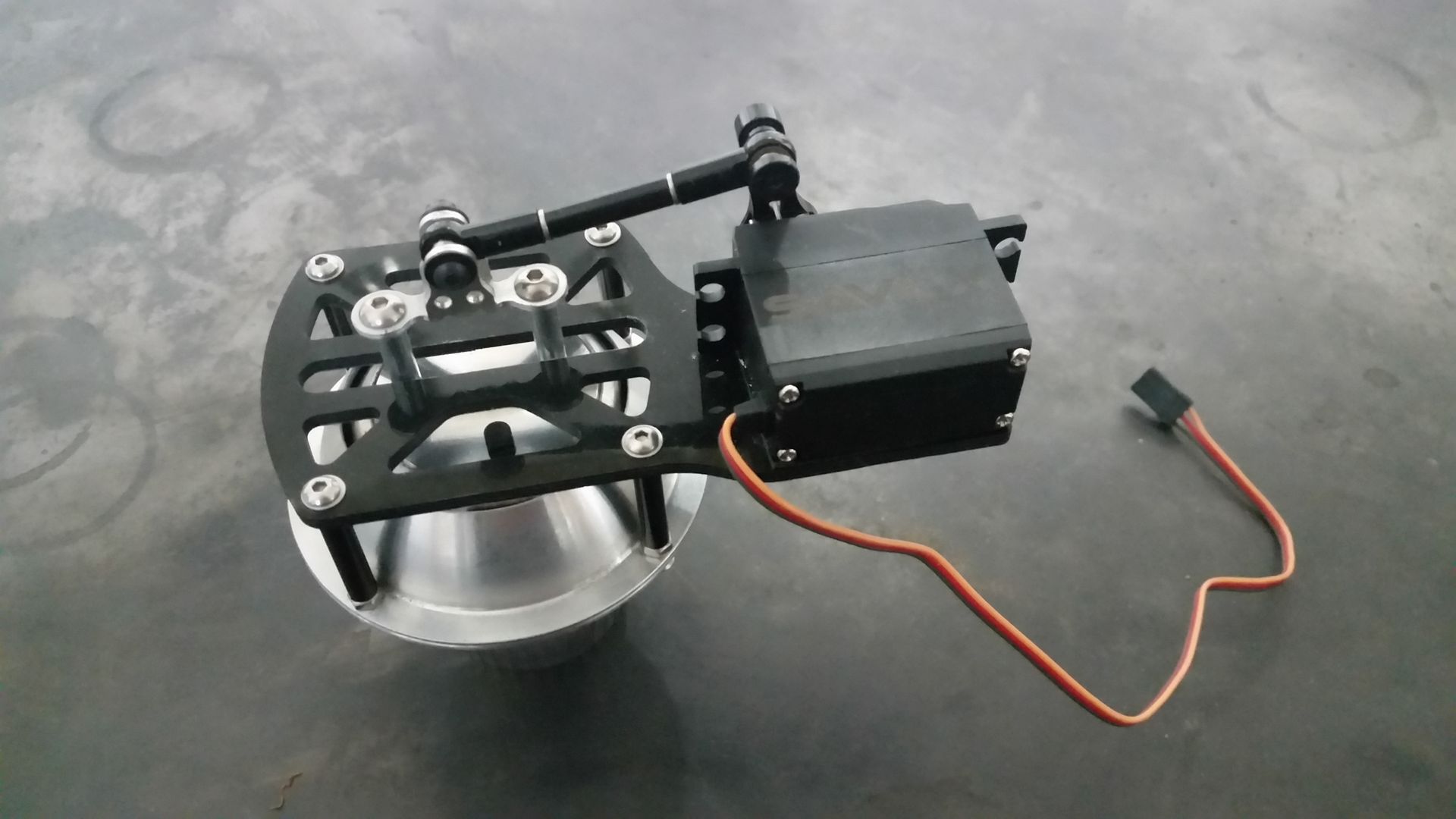

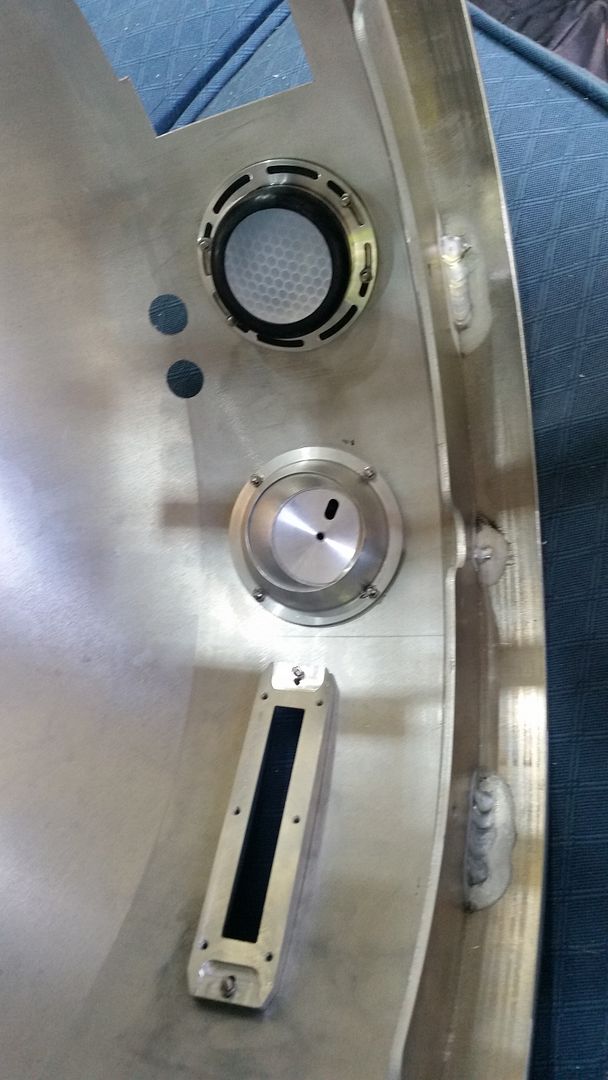

James made me some beautiful steel studs to mount to the rockler. These were 13mm diameter, and M5 thread in the bottom, 5 of 13.3mm and 1 of 23.3mm. The holes in the dome base were opened to 14mm, and magnets were suspended on carbon plates using more ali standoffs of 15mm and 25mm.

(early version of arm and studs)

(Finished version)

The dome lifts off really nicely and the dome is aligned by the pegs, so the connector clicks on beautifully. :) I may redo one of the pegs, so there are 2 long ones, just to be extra safe.

This still leaves the bottom of the rockler available for the dome drive gear. :D